The fashion industry is undergoing a radical transformation, shifting from mass production to hyper-personalized, made-to-measure garments. At One-to-One Systems, we are pioneering this change with cutting-edge AI-driven customizable fashion algorithms.

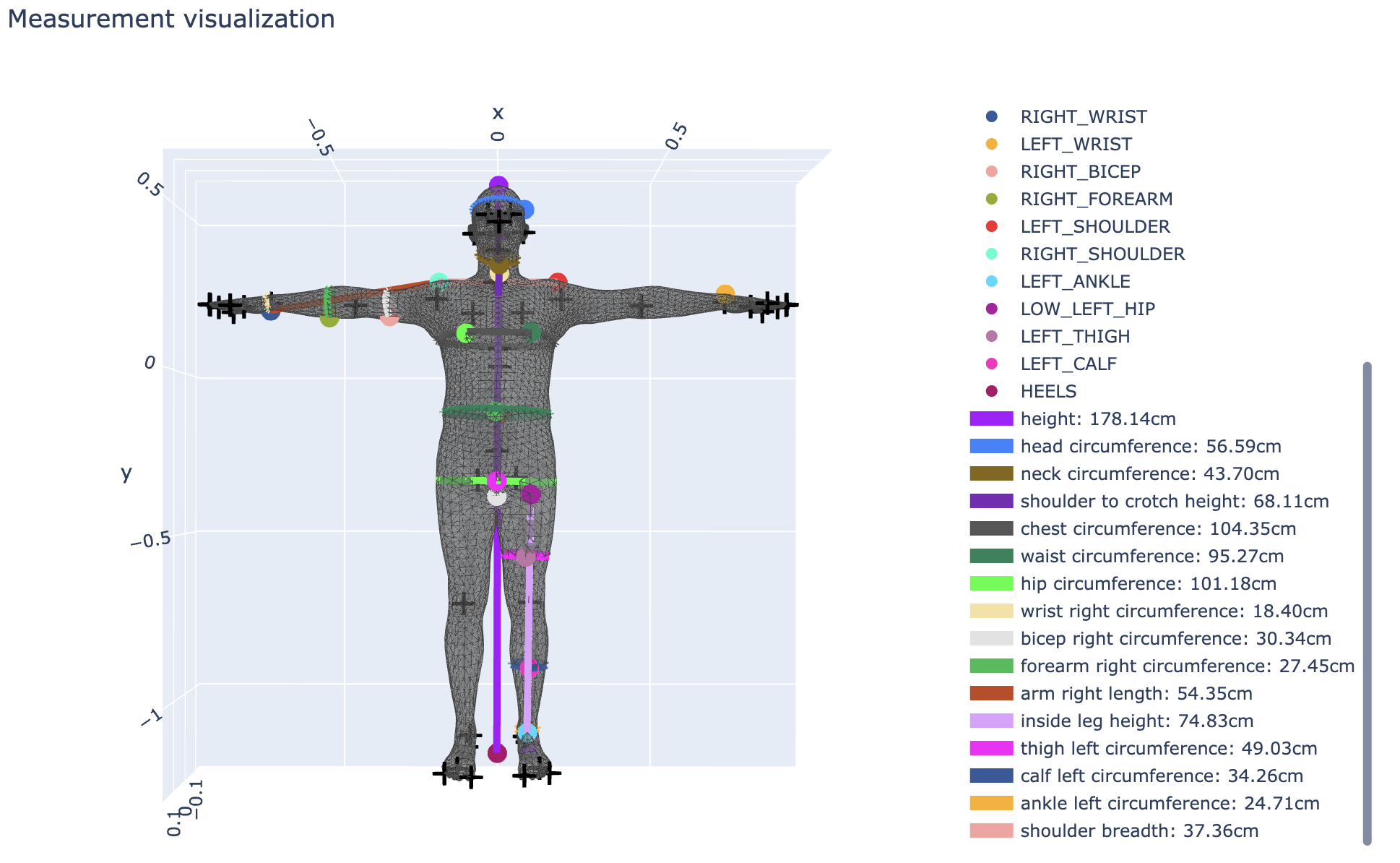

The core of this project revolves around an advanced 3D body estimation pipeline, where we transform a set of critical body measurements into an SMPL (Skinned Multi-Person Linear) model of the human body. This precise digital twin allows us to extract accurate anthropometric measurements, ensuring a perfectly fitted block template for garment production.

This post delves deep into the technology that makes this possible.

Problem Statement

Traditional fashion sizing systems rely on predefined size charts, leading to poor-fitting clothes for many consumers. Even in made-to-measure clothing, traditional measurement techniques are prone to human error, making them inefficient and costly.

By leveraging deep learning, parametric body modeling, and optimization algorithms, we developed a scalable and highly accurate system that takes a small set of user-provided measurements and estimates a full 3D SMPL model, which is then used to extract precise garment patterns.

From Measurements to 3D Models

Our algorithm consists of three major stages:

- Measurement to SMPL Model Estimation

- Accurate Anthropometric Extraction

- Block Template Generation for Custom Garments

Let’s break down each stage.

Extracting Precise Anthropometric Measurements

Once the personalized SMPL model is generated, we extract detailed anthropometric features, including:

- Chest circumference

- Waist and hip measurements

- Shoulder width

- Inseam and outseam lengths

These extracted values are far more accurate than direct user measurements, as they leverage 3D spatial consistency.

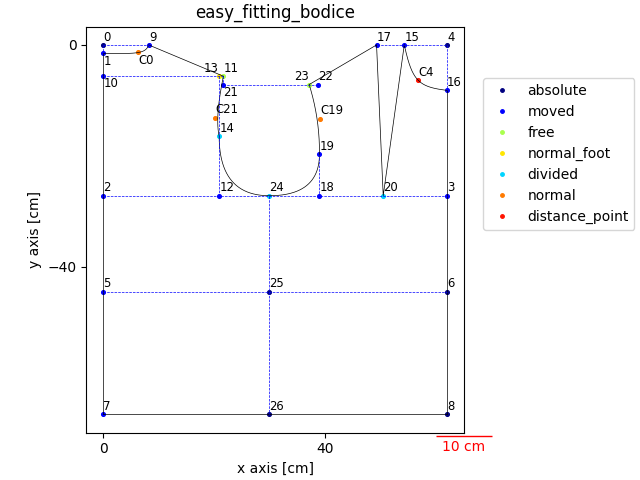

Generating Block Templates for Custom Garments

Using the extracted measurements, we generate block templates—the fundamental blueprints for custom garments. Each garment type requires specific template calculations:

Upper Body (Shirts, Jackets)

\[L_{\text{shirt}} = f_{\text{upper}}(\text{chest},\ \text{shoulder},\ \text{sleeve length})\]Lower Body (Pants, Skirts)

\[L_{\text{pants}} = f_{\text{lower}}(\text{waist},\ \text{hip},\ \text{inseam},\ \text{outseam})\]These templates are adjusted dynamically based on fabric elasticity, desired fit (tight, regular, loose), and ease allowances.

Results: The Accuracy of AI-Powered Fashion

Our system achieves remarkable accuracy, with measurement deviations of less than 3 mm compared to traditional tailor-made garments. This level of precision outperforms human-tailored measurements and is significantly faster and more scalable.

Key Benefits:

- Near-perfect fit for all body shapes

- Fully automated pipeline from input measurements to garment templates

- Scalable for mass customization in fashion production

Impact on the Fashion Industry

With the rise of on-demand fashion, our system paves the way for:

- Zero-inventory clothing production (reducing waste)

- Personalized clothing e-commerce (AI-generated virtual fitting)

- Accessible made-to-measure clothing (cost-effective production)

We believe this technology will be a game-changer in how clothes are designed, fitted, and manufactured.

Final Thoughts

The world of fashion is changing. AI-driven garment customization is no longer the future—it’s happening now.

By combining deep learning, 3D body modeling, and precise anthropometric extraction, we’ve built a system that bridges the gap between mass production and tailor-made perfection.